Ever unboxed a luxury candle and thought, “Wow, this packaging feels special”? That perfect fold. The smooth curve of a window. The satisfying tuck as you open the box. It’s not just pretty—it’s the result of smart, intentional die cutting.

In this guide, we’ll walk you through how the die slice workshop works, why it matters for candle packaging, and how brands (just like yours!) use it to elevate both the look and sense of their products. We’re keeping it simple, practical, and real, just like a cozy discussion with your favorite packaging expert.

What Is Die Cutting?

Imagine using a cookie cutter, but for boxes. Die cutting is the process where machines stamp out custom shapes and designs from waste of packaging material, generally cardboard or kraft board. It’s the secret behind those crisp edges, twisted windows, custom tuck-in flaps, and creative designs.

Think of it as tailoring for packaging.

Where a plain box may just fold into a square, die-cutting lets you:

- Add windows to showcase the candle inside

- Create custom folds for elegant unboxing

- Incorporate handles, locks, or decorative curves

- Produce uniform shapes for bulk orders—every box matches, every time

So when someone picks up your candle box and goes, “This feels premium,” it’s not by accident—it’s the die cutting.

Why Candle Brands Love Die-Cut Boxes

Let’s get real: candles are all about the experience.

Customers aren’t just buying wax and wick—they’re buying ambience, mood, and story. Packaging sets the tone even before the candle is lit.

Here’s why die-cutting is a perfect match for high-end candle brands:

1. Showcases the Candle Without Opening the Box

Windows cut into the front or side of the box let customers peek at the candle. This creates curiosity, gives a preview of colors or texture, and shows off quality—all while keeping the candle secure.

2. Creates a Premium Unboxing Experience

Luxury is in the details. A custom tuck tab or magnetic closure adds just enough “ooh” to make unboxing feel like opening a gift. That’s packaging that gets remembered (and Instagrammed).

3. Improves Brand Recognition

When your box has a signature cut-out (say, a flame shape or an embossed logo fold), it becomes part of your identity. Customers start to recognize your box style, not just your label.

How Die Cutting Works (Simplified)

Let’s break this down into real steps—no factory jargon:

Step 1: The Design Phase

This is where the magic starts. A dieline is created—this is a 2D flat layout of your future box. Think of it as the blueprint that shows exactly where the box will be cut, folded, and glued.

At this stage, you’ll also decide:

- Where to place windows

- What kind of closure or flap do you want

- If you want embossing or debossing

- Any structural flourishes (e.g., curved edges, slide-out trays)

Step 2: Creating the Die

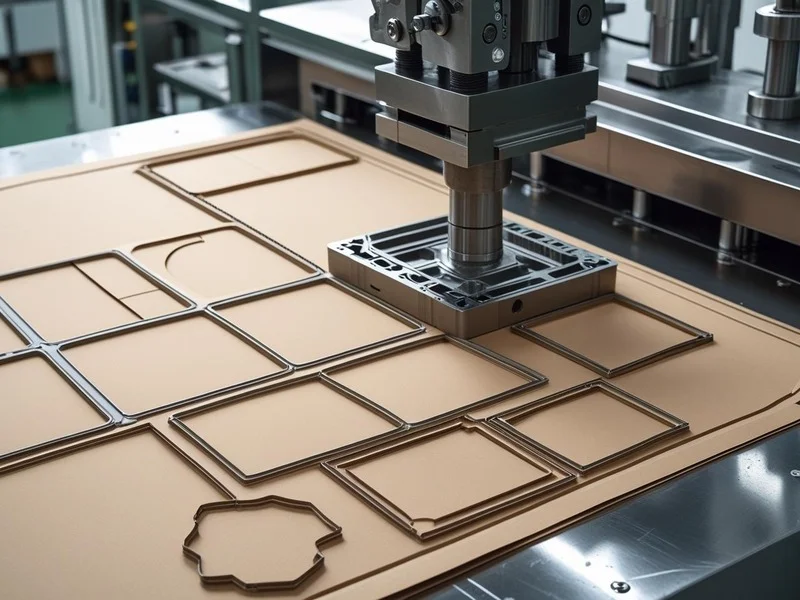

Next, a steel-rule die is crafted. It looks like a giant cookie cutter with blades bent into the shape of your box. This die will be pressed onto your box material to cut it out.

Step 3: Cutting the Boxes

Sheets of your packaging material( cardstock, kraft board, etc.) are fed through the die-cutting machine. The die prints out the shapes with exact perfection, over and over, icing your packaging is harmonious, sharp, and professional.

Step 4: Folding and Gluing

After cutting, the flat boxes are crinkled, folded, and fused where demanded. Also, they’re smoothed and packed for you, ready to be assembled.

Customization Options With Die Cutting

Die-cutting is more than just cutting shapes. It gives you creative freedom. Some ideas?

- Logo-shaped windows

- Wave-shaped edges for a calming, natural feel

- Tuck flaps that snap gently into place

- Slide-out drawer-style boxes for a luxe presentation

- Embossed flame shape on the lid of your candle box

- Handle cuts for easy carrying at markets or pop-ups

There’s no rulebook here—just smart design paired with purpose.

Popular Box Styles That Use Die Cutting

At this point, you may wonder what types of candle boxes benefit most from die cutting. Let’s look at a few favorites:

| Box Type | Why It Works |

| Window Box | Offers visibility of the candle, boosts shelf appeal |

| Two-Piece Rigid Box | Ideal for luxury candles; allows custom inserts & reveals |

| Drawer Box (Slide Out) | Elegant opening experience; feels like opening a jewelry box |

| Tuck-End Box | Simple yet customizable with creative flaps & locks |

| Pillow or Curved Box | Adds a soft, elegant shape—great for gift packaging |

Each of these can be customized with die cuts to match your brand vibe.

Tips for Designing Candle Boxes with Die Cutting

Want to get it right from the start? Here are some real-world tips we share with clients:

Think Inside the Box

Consider how your candle fits—loose is bad, tight is worse. Die cutting can be used to add internal holders or inserts that cradle your candle perfectly.

Watch Window Placement

Make sure the cutout doesn’t block important product info (like burn time or ingredients). If it’s a scented candle, let customers see the wax color—that’s part of the appeal!

Don’t Forget Durability

Thin, flimsy cuts can weaken your box. We always test designs for shipping strength.

Add Texture with Finishes

Combine die-cutting with foil stamping, spot UV, or embossing to make the whole package feel rich.

Is Die Cutting Worth the Cost?

Short answer: Yes, especially if you’re positioning your candles as a luxury or gift item.

While custom die-cutting involves some initial setup cost (creating the die mold), it pays off:

- Your product stands out immediately

- You can charge more per item

- Customers associate your packaging with quality

- You get more word-of-mouth and unboxing buzz

Ordering in bulk reduces the cost per unit dramatically, and most small businesses see strong ROI when using die-cut packaging on their hero products.

Final Thoughts

Die cutting isn’t just for show. It tells your client This candle matters. This brand cares. This moment is special.

Whether you’re launching a minimalist soy wax collection or a vacation gift set, your packaging plays a starring part. With smart bone-cut design, you’re not just belting a candle, you’re presenting an experience.

So, coming time you hold an impeccably shaped candle box, flash back there’s a thoughtful process behind every pack and wind, and now, you are in on the secret.