In the world of high-end product packaging, first impressions are everything. For candle brands aiming to exude elegance, warmth, and craftsmanship, the box matters just as much as the candle inside. That’s where die cutting comes into play.

If you’ve ever wondered how your favorite luxury candle boxes achieve such precise folds, smooth curves, or custom shapes that seem to fit the candle like a glove, you’re about to get a behind-the-scenes look at the unsung hero of the packaging world.

What Is Die Cutting?

Die cutting is the process of cutting, shaping, and scoring materials like paperboard or cardstock using a customized tool called a die. Think of a die as a cookie cutter, but for packaging. It’s engineered to stamp out exact shapes repeatedly, allowing for:

- Clean cuts

- Fold lines (scores)

- Windows or intricate design cutouts

- Tabs, flaps, and locking features

When you’re designing luxury candle boxes, die cutting ensures your packaging not only protects your product but also elevates your brand.

How the Die-Cutting Process Works

Here’s how it typically goes down in a packaging facility:

1. Custom Die Creation

Every luxury candle brand is different. Box sizes, shapes, and closure styles vary—so packaging companies design a custom die based on your specifications.

This die consists of sharp blades (for cutting) and dull blades (for scoring), mounted onto a flat wooden base in the shape of your box’s layout (a dieline).

2. Material Setup

Once your preferred material—say, high-quality kraft board or coated paperboard—is selected, it’s laid flat and passed through a press fitted with the die.

3. Cutting & Scoring

As the die presses down, it slices through the board with incredible accuracy, creating the exact box shape and fold lines needed for final assembly.

4. Ejection

Many dies include rubber “ejection” strips that gently push the newly cut pieces away from the blades, ensuring speed and clean results.

Why Die Cutting Matters for Luxury Candle Boxes

Now that we know how it works, let’s talk about why it’s so crucial for upscale candle packaging.

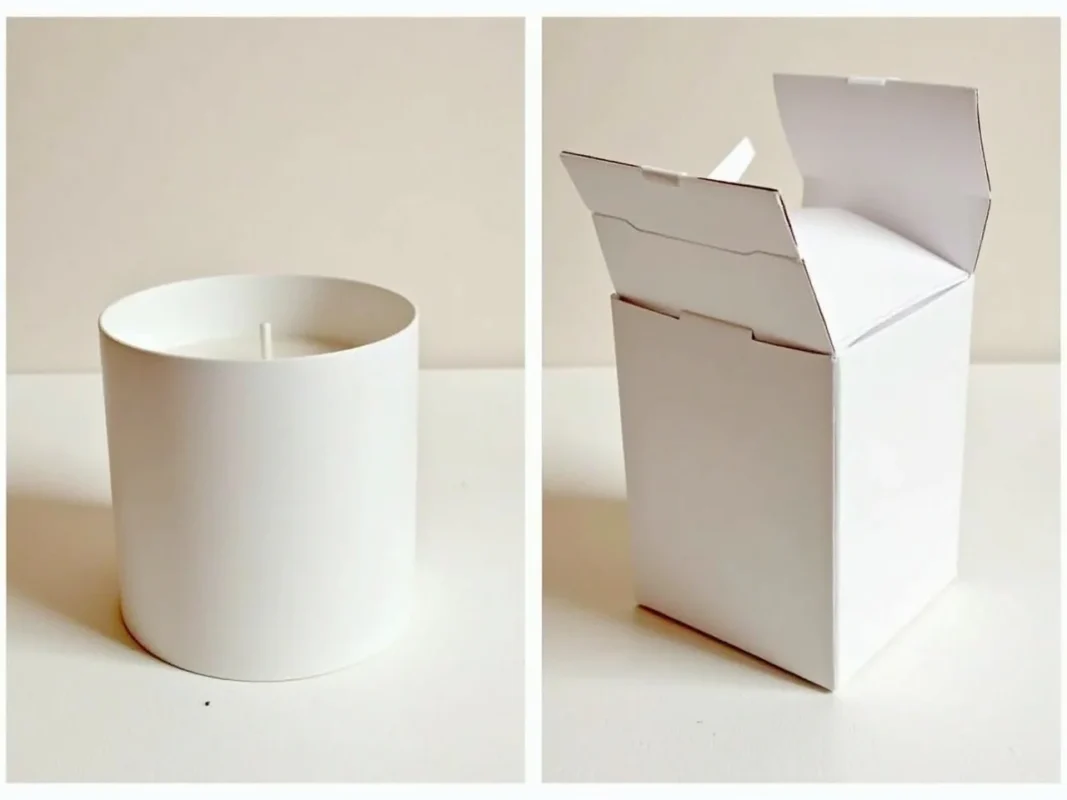

1. Perfect Fit for Your Product

You’re not selling just any candle. You’re selling a luxury experience. Die cutting ensures your box dimensions are spot-on, fitting your candle jar, tissue paper, inserts, or velvet bag perfectly. No wiggle. No wasted space.

2. Custom Shapes and Unique Structures

Want a hexagonal candle box? A heart-shaped window? A two-piece rigid box with a slide-out tray? Die cutting is the only way to bring these shapes to life. It gives your brand the freedom to break away from boring square packaging.

3. Enhanced Protection

Candle jars—especially glass ones—are fragile. A precisely die-cut box ensures snug inner compartments or inserts that keep your candle safe during shipping and prevent breakage.

4. Branding That Feels Intentional

Luxury is in the details. A box with perfectly aligned folds, sharp corners, or subtle die-cut embossing tells your customer: this brand cares. Combined with foil stamping or spot UV, die cutting completes that polished, high-end feel.

Examples of Die-Cut Features for Candle Boxes

Here’s a breakdown of the creative things you can do with die cutting:

| Die-Cut Feature | Purpose | Luxury Touch |

| Custom window cutouts | Reveal the candle scent or color | Shapes like stars, leaves, flames |

| Inserts | Hold candles securely in place | Can be velvet-lined or branded |

| Lock tabs & flaps | Secure closures without glue | Clean assembly, reusable box |

| Embossed logo panels | Add dimension to your brand | Looks and feels premium |

| Fold-flat designs | Save space during shipping | Cost-efficient yet elegant |

Can Die Cutting Be Sustainable?

Absolutely. Many luxury candle brands today are moving toward eco-friendly packaging, and die cutting aligns with that mission.

- Minimal waste: Die cutting reduces material waste compared to manual cutting.

- Recyclable materials: Use FSC-certified paperboard or biodegradable cardboard.

- Efficient production: Fast and consistent cutting reduces energy usage.

- Flat shipping: Many die-cut boxes are foldable, lowering transport emissions.

If you’re marketing your candles as eco-luxury, your box can walk the walk.

How Luxury Brands Use Die Cutting in Candle Packaging

Let’s take a look at how some types of candle brands benefit from die cutting:

Boutique Candle Lines

Small-batch candle makers often choose unique box shapes or window cutouts that show off their colorful wax or label design.

Home Décor Brands

These businesses want high-end boxes that can double as gift packaging—complete with magnetic flaps, ribbons, or embossed branding, all possible through precise die cutting.

Scented Spa Candles

Luxury spa-style candles often come in minimalist rigid boxes, where die cutting ensures structural integrity while maintaining a clean look.

Die Cutting vs. Traditional Cutting

| Feature | Die Cutting | Manual/Traditional Cutting |

| Precision | Extremely accurate | Inconsistent cuts |

| Speed | High-speed mass production | Slower process |

| Customization | Virtually unlimited | Limited shapes |

| Best For | Luxury packaging, custom designs | Simple bulk orders |

If your packaging goal is luxury presentation, there’s no real alternative.

What to Expect When Ordering Die-Cut Candle Boxes

When working with a packaging supplier like Luxury Candle Boxes, you’ll typically go through these steps:

- Consultation – You share your candle size, branding vision, and quantity.

- Dieline creation – We develop a structural template based on your specs.

- Material selection – Choose your board type, finishes, and insert needs.

- Prototype – We send you a sample (physical or digital) to test fit and design.

- Production – Once approved, we cut and assemble boxes at scale.

Our team at Luxury Candle Boxes ensures every die cut is clean, consistent, and exactly what your product deserves.

FAQ: Die Cutting & Candle Boxes

Q: How long does it take to produce die-cut boxes?

A: Prototypes typically take 5–7 business days, and full production runs can be completed within 10–14 days, depending on volume.

Q: Can I order die-cut boxes in small quantities?

A: Yes! We specialize in both low-MOQ boutique orders and larger wholesale runs.

Q: What finishing options pair well with die cutting?

A: Foil stamping, soft-touch lamination, embossing, and spot UV are top choices for a luxury candle experience.

Q: Are die-cut boxes more expensive?

A: While they may cost more than standard cartons, the investment pays off in branding, customer perception, and protection.

Final Thoughts: Why Die Cutting Is a Game-Changer for Luxury Candle Packaging

The next time you hold a luxury candle box that opens with a soft click and reveals the product like a treasure chest, remember that’s die cutting at work.

It’s not just about making boxes. It’s about making experiences.

At Luxury Candle Boxes, we help brands turn their candles into luxury gifts, retail-ready showcases, and unforgettable customer moments—all through the power of precise, thoughtful die cutting.