Creating custom packaging for your luxury candles isn’t just about choosing pretty colors and putting your logo front and center—it’s about precision. When you’re producing packaging in large quantities (say 1,000 boxes or more), even the tiniest design error can cost you time, money, and brand reputation.

That’s where a die-line comes in.

In this article, we’ll present a dieline, explain how to use it correctly, and explain why it’s especially important when designing custom luxury candle boxes for bulk production. Whether you’re new to packaging format or want to ensure your next print run runs smoothly, this beginner-friendly manual will help.

What is a Dieline?

A dieline is a 2D template used in packaging format. It outlines just how your box will be published, cut, and tucked during the show. Think of it like a stencil or blueprint that shows both the developer and the printer.

For luxury candle packaging, dielines help ensure that:

- The box fits your product perfectly

- All artwork and text stay within safe zones

- Cuts and folds are accurate to avoid misalignments

- Your high-end brand image is preserved across every unit

When printed and tucked, the dieline evolves a 3D box that not only saves your candle but also remembers your aesthetic, story, and cost point.

Why Dielines Matter for Luxury Candle Packaging

If you’re printing 1,000 custom candle boxes or more, you can’t afford guesswork. Small issues in your dieline could result in thousands of unusable or off-brand packages.

Here’s why dielines are non-negotiable for luxury candle packaging:

- Consistency: Provides every box tucks in the same manner, uniformity issues in excellent products.

- Accuracy: Prevents misprints or inadequate fit (candles are heavy; your box ought to keep up).

- Cost control: Avoids reprints and destruction due to design mistakes.

- Efficiency: Streamlining shows when operating with big books.

At higher order quantities, even a 1mm alignment issue can become a big (and expensive) problem.

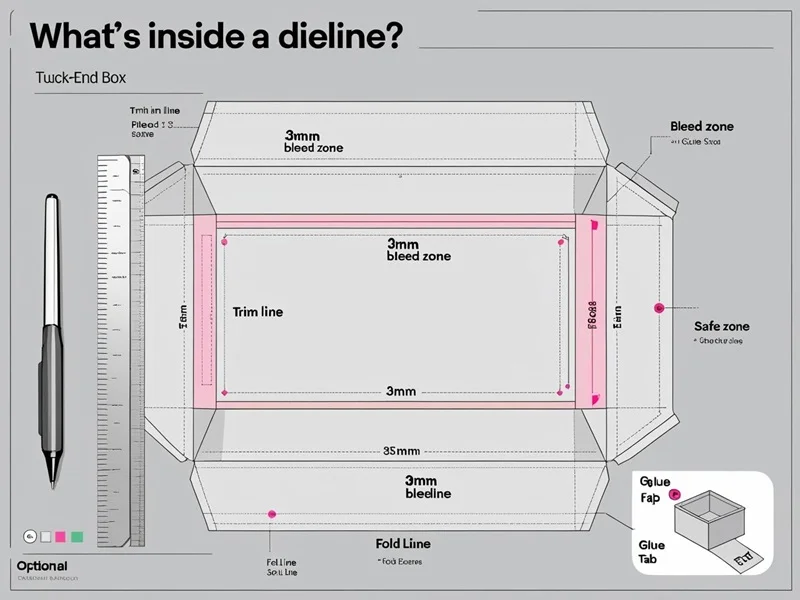

What’s Inside a Dieline?

Here’s what you’ll typically see in a dieline for candle packaging:

| Element | What It Means |

| Cut lines (solid) | Where the box will be cut out |

| Fold lines (dashed) | Where the packaging folds to form the final 3D box |

| Bleed area | Extends beyond cut lines to prevent white edges after trimming |

| Safe zone | Area within which to keep all important text/images |

| Glue flaps | Tabs where glue is used to hold the box together |

If you’re functioning with a packaging supplier or a printer, they’ll usually supply a dieline based on your box size and type. If not, you can order one or have a structural engineer make it for you.

How to Design Using a Dieline

Once you have your dieline file (usually in PDF, AI, or EPS form), it’s time to use your branding and painting. You’ll use a design schedule like Adobe Illustrator to work on the dieline.

Step 1: Understand the Dieline Layout

Per panel on the dieline means a part of the package: front, back, top, base, and sides. It’s necessary to imagine how it folds into a 3D design.

Tip: Print out a document and fold it by writing if you need a graphic direction.

Step 2: Keep Key Elements Inside Safe Zones

Things like:

- Your logo

- Product name

- Scent (e.g., “Midnight Jasmine”)

- Instructions or burn warnings

- Barcodes or batch numbers

These all need to stay well within the safe area so they aren’t cut off or wrapped awkwardly.

Step 3: Extend Backgrounds into the Bleed

Make sure your background colors or patterns extend into the bleed area. This prevents unintentional white edges during trimming.

Step 4: Watch Your Fold Lines

Avoid placing text directly on a fold unless it’s intentional and legible. If your brand uses minimalist or luxury fonts, they can look crooked or get cracked on the crease.

Step 5: Check Orientation

Double-check that all text and images are correctly aligned for how the box will stand. Upside-down branding is a costly mistake at high volumes.

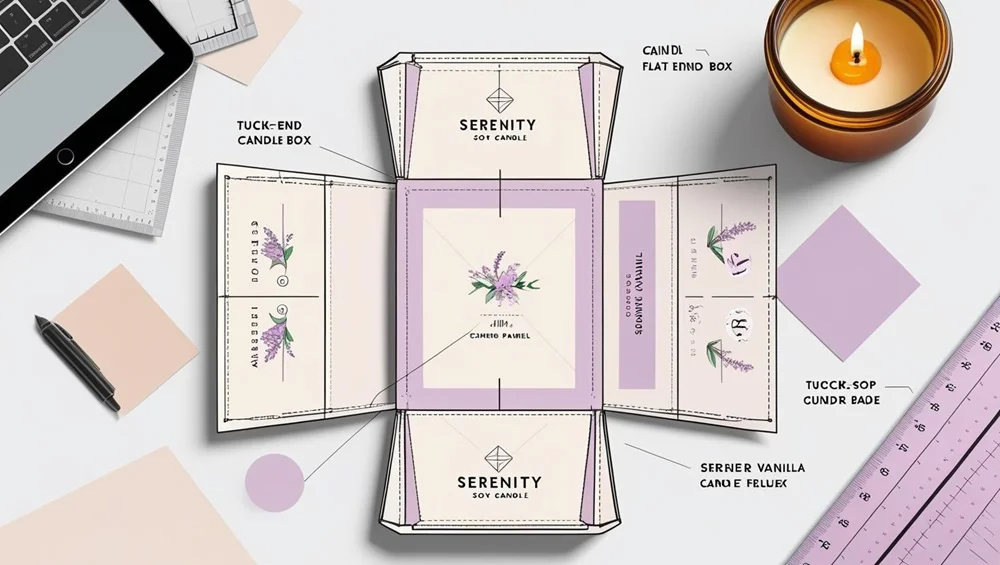

🕯 Luxury Candle Box Styles and Dielines

Here are some common candle box styles and how dielines apply to each:

| Box Style | Use Case | Dieline Complexity |

| Straight tuck end | Simple retail candle box | Low |

| Two-piece rigid box | Premium gifting or subscription boxes | Medium to high |

| Sleeve and tray | Elegant unboxing experience | Medium |

| Magnetic closure box | Ultra-luxury candles (above $50 range) | High |

Your dieline should match the box style you choose. If you’re unsure, ask your packaging provider to show you dieline options that suit your candle size and brand look.

How We Help at Custom Luxury Candle Boxes (Your Partner in Precision)

At Custom Luxury Candle Boxes, we guide you through every step of the dieline process—especially when you’re ordering 1,000+ units and need precision.

Here’s how we support you:

- Box style consultation: We help you choose a packaging type that fits your candle’s size, weight, and aesthetic.

- Dieline templates: We provide ready-to-use dielines customized to your order.

- Design support: Need help applying your artwork? Our in-house designers can do that for you.

- 3D mockups: See a virtual version of your final box before printing starts.

- Proof checks: Every dieline gets reviewed before production to catch errors early.

Our goal is to make sure your luxury candle boxes don’t just look stunning—they work flawlessly too.

Pre-Production Checklist

Before you hit “go” on 1,000 printed boxes, run through this checklist:

Dieline matches the correct box size

All artwork fits within safe zones

Bleed margins are set up properly

No important text is near folds or glue areas

You’ve received a final proof or 3D mockup

Your brand colors are CMYK and ready for print

The more thorough you are now, the smoother production will be.

Final Thoughts

When you’re producing bespoke luxury candle packaging in size, your dieline is more than just a specialized file—it’s the basis of your label’s first appearance.

Done right, it keeps your packaging sharp, elegant, and error-free across 1,000+ units. Done wrong? It can cause expensive delays, waste, and missed sales.

Whether you’re working with your designer or partnering with experts like us at Custom Luxury Candle Boxes, always prioritize precision when working with dielines.

Need a dieline made for your next candle packaging project? Reach out—we’re happy to send over dieline templates or create one based on your exact needs.